Global coordinate measuring

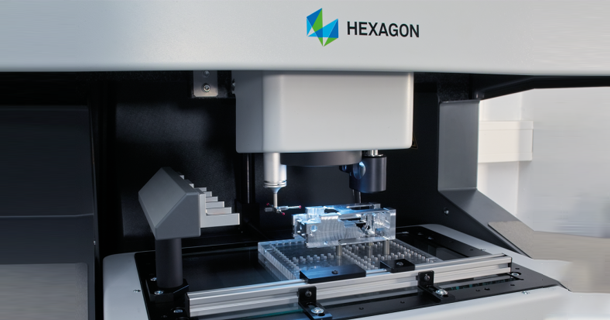

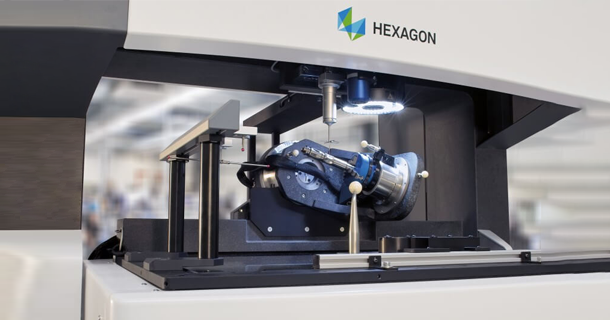

We offer precision part inspection using our very own Global coordinate measuring machine from Hexagon Manufacturing Intelligence.

Using a range of contact probes along with the latest version of the PC-DMIS program, our two trained CMM programmers can create efficient custom measurement routines for individual parts or batches with precision down to the micron.

We are happy to offer CMM dimensional inspection services including First Article Inspections (FAI) and Partial First Piece (PFP) inspections to compare manufactured parts from a range of industries to CAD models or drawings. Our machine can fit parts up to 16”x16”x24” and can measure features as small as 2 millimeters.

CMM

Coordinate Measuring Machine

A Coordinate Measuring Machine (CMM) replaces the manual quality control (QC) processes involved with verifying the dimensions of metal parts via micrometers and height gauges.

The machine uses coordinate technology with a ruby stylus tip to determine the height, width, & depth of items that are being observed on an X,Y, Z axis.

The coordinate measurements taken are then compared to the CAD drawings associated with each part.

This machine has the option to allow an operator to maneuver the stylus to take measurements or, use direct computer control (DCC) to take fully automated measurements of the item. This allows us to take items that have been machined on our HAAS and complete QC inspections with extreme accuracy.